Cruise Ship Propeller Cost

Propeller moves forward 10inches for every complete turn it has a 10inch nominal pitch.

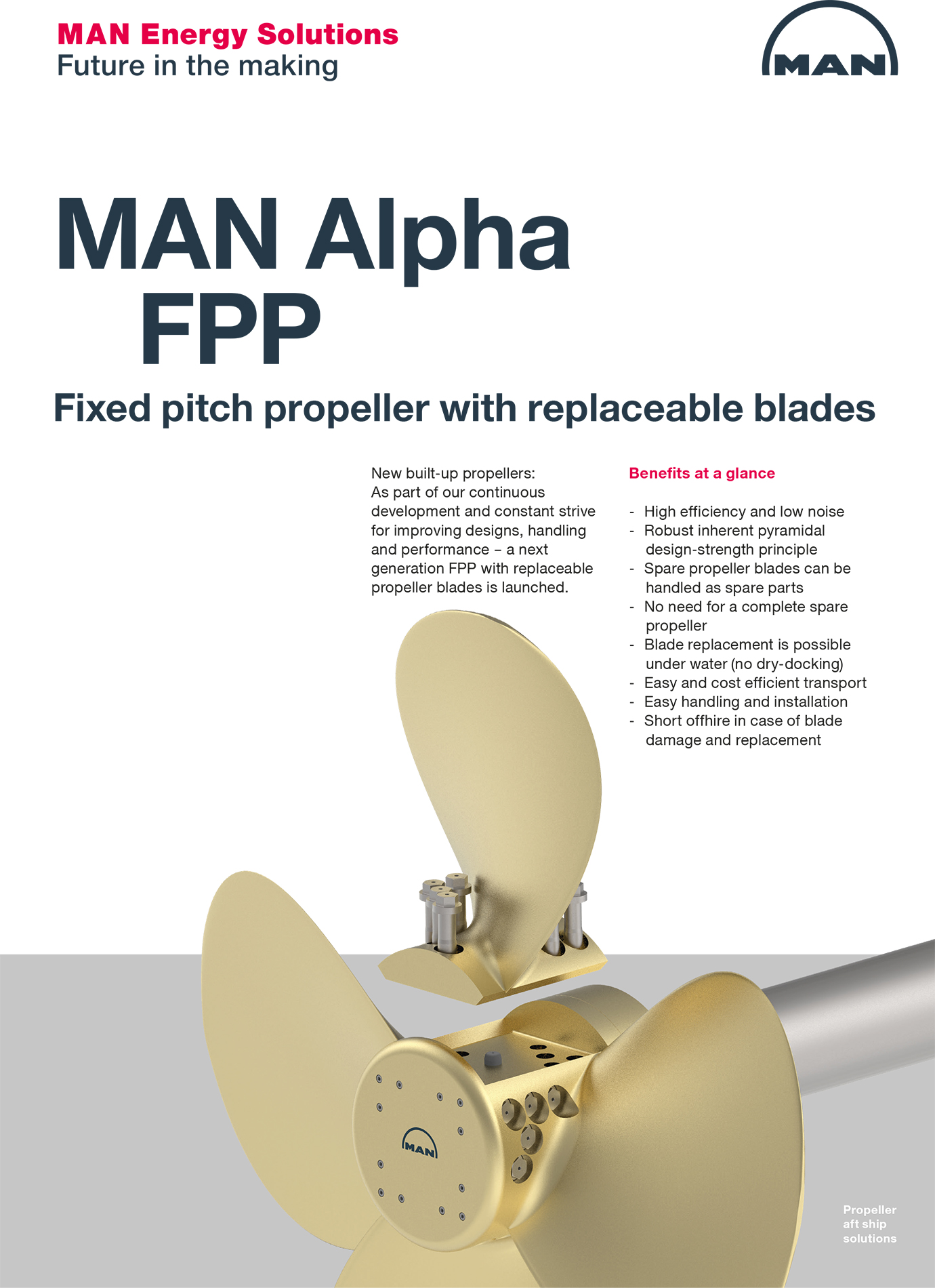

Cruise ship propeller cost. Cruise ships are built because they are big businesses. Fuel crew and maintenance are chief among the main culprits hogging the majority of costs. A revolution in ship propulsion technology.

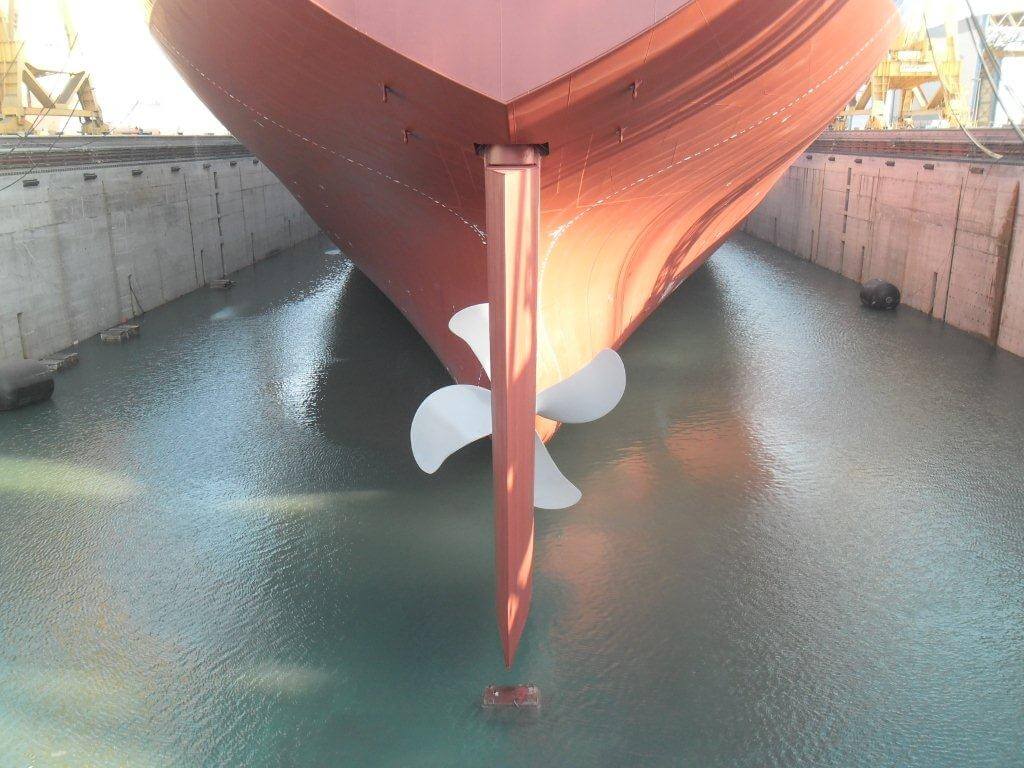

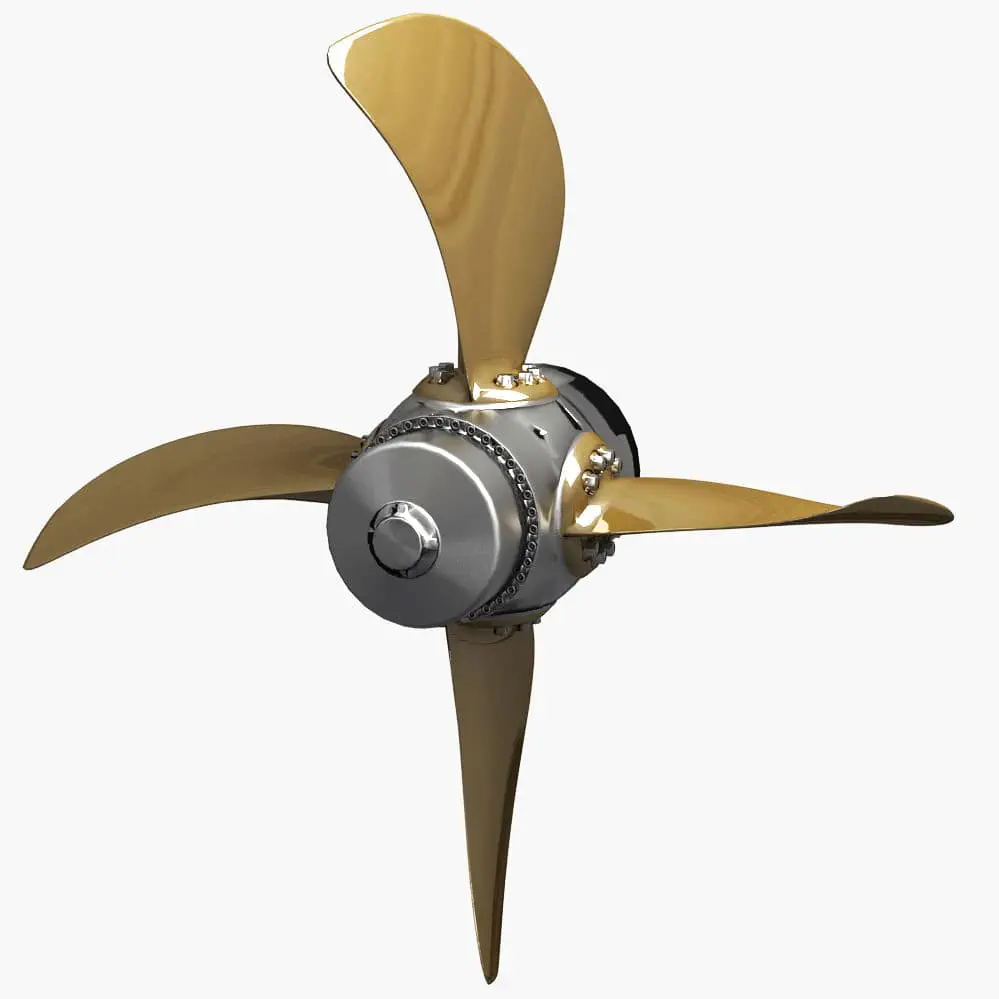

These huge propellers rely on torque or power rather than speed to provide the motion required to propel a huge vessel often weighing over 200000 tons. The pulling propeller eats from the homogenous field of water. The propellers measured 72 meters.

He was fired for not adhering to the code of conduct in his contract. Here are the basics on how a cruise ship is driven through the ocean. In this aspect the hull form of.

At the shipowners request Thordon Bearings the market leader in water lubricated bearing. In this case the propeller is cast in one piece and is made of a complex. Lines price the cruise ships building cost by the number of beds the marine term is berths.

PROPELLER RECONDITIONING and RE-PITCHING SERVICE. As you might imagine driving something the size of a skyscraper through narrow waterways and then precisely docking it between various obstacles is no easy task. The cruise industry is a fast-growing category in the leisure travel market and cruise performance monitoring for your.

Switzerland-based MSC Cruises has agreed to install a water-lubricated propeller shaft system built by Canada-based Thordon Bearings aboard the first of two new cruise ships currently under construction Thordon Bearings announced in an emailed statement. With rising demand for luxury travel more cruise operators are turning to digital solutions to help cope with cost pressures due to high fuel consumption activities and fleet operational efficiency. Seawise Giant was the longest ship ever built.